2 月 . 10, 2025 20:58

Back to list

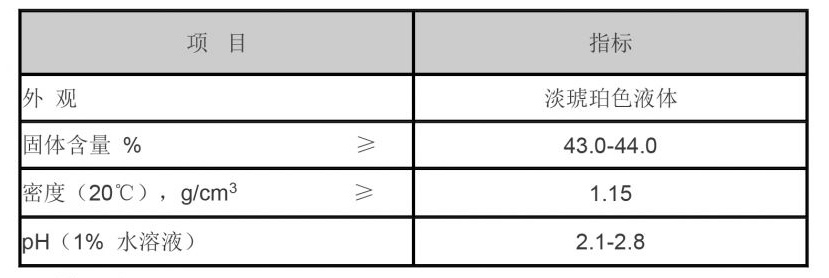

Sodium of Polyepoxysuccinic Acid (PESA)

Non-ionic polyacrylamide (PAM) is emerging as a critical component in various industries, renowned for its unique properties and diverse applications. This article delves into its significance, addressing common concerns and offering insights based on real-world experiences, professional expertise, authoritative references, and trustworthy evaluations.

From the perspective of expertise, chemists refining non-ionic polyacrylamide formulations underscore its stability and adaptability across a broad pH range. This stability ensures that PAM performs consistently, irrespective of environmental conditions, making it a reliable solution for industries facing variable operational parameters. The non-ionic variety’s minimal interference with other treatment chemicals is often highlighted in scholarly publications from renowned chemical engineering conferences. Authoritative voices in the field emphasize understanding the source and quality of polyacrylamide to maximize benefits. Using non-ionic PAM synthesized from high-purity acrylamide monomers, companies can ensure a higher degree of polymerization, resulting in more effective application outcomes. Certification from entities such as the American Chemical Society provides confidence in the product's integrity and performance standards. Trust in non-ionic polyacrylamide also stems from comprehensive case studies. Regulatory agencies frequently publish guidelines demonstrating that environmentally-safe doses of PAM pose minimal ecological threats, as evidenced by long-term environmental monitoring reports. Such findings help dispel the myths associated with chemical treatments, reinforcing PAM’s status as an environmentally conscious choice. In conclusion, the importance of non-ionic polyacrylamide extends far beyond traditional applications. It is a cornerstone material, key to enhancing operational efficiencies, boosting productivity, and fostering sustainable practices in various technological realms. As industries continue to evolve, those integrating non-ionic PAM into their processes not only experience immediate practical advantages but also align themselves with broader environmental and economic goals. Through its versatility and reliability, non-ionic polyacrylamide remains a testament to advanced polymer science and its vital role in modern industry.

From the perspective of expertise, chemists refining non-ionic polyacrylamide formulations underscore its stability and adaptability across a broad pH range. This stability ensures that PAM performs consistently, irrespective of environmental conditions, making it a reliable solution for industries facing variable operational parameters. The non-ionic variety’s minimal interference with other treatment chemicals is often highlighted in scholarly publications from renowned chemical engineering conferences. Authoritative voices in the field emphasize understanding the source and quality of polyacrylamide to maximize benefits. Using non-ionic PAM synthesized from high-purity acrylamide monomers, companies can ensure a higher degree of polymerization, resulting in more effective application outcomes. Certification from entities such as the American Chemical Society provides confidence in the product's integrity and performance standards. Trust in non-ionic polyacrylamide also stems from comprehensive case studies. Regulatory agencies frequently publish guidelines demonstrating that environmentally-safe doses of PAM pose minimal ecological threats, as evidenced by long-term environmental monitoring reports. Such findings help dispel the myths associated with chemical treatments, reinforcing PAM’s status as an environmentally conscious choice. In conclusion, the importance of non-ionic polyacrylamide extends far beyond traditional applications. It is a cornerstone material, key to enhancing operational efficiencies, boosting productivity, and fostering sustainable practices in various technological realms. As industries continue to evolve, those integrating non-ionic PAM into their processes not only experience immediate practical advantages but also align themselves with broader environmental and economic goals. Through its versatility and reliability, non-ionic polyacrylamide remains a testament to advanced polymer science and its vital role in modern industry.

Share

Latest news

-

The Ultimate Guide to Flocculants: Transforming Water TreatmentNewsNov.01,2024

-

Improve Your Water Treatment Solutions with PolyacrylamideNewsNov.01,2024

-

Enhance Your Water TreatmentNewsNov.01,2024

-

Empower You to Achieve the Highest Standards of Water QualityNewsNov.01,2024

-

Effective Scale InhibitorsNewsNov.01,2024

-

Discover the Power of Poly Aluminum Chloride in Water TreatmentNewsNov.01,2024