2 月 . 10, 2025 21:34

Back to list

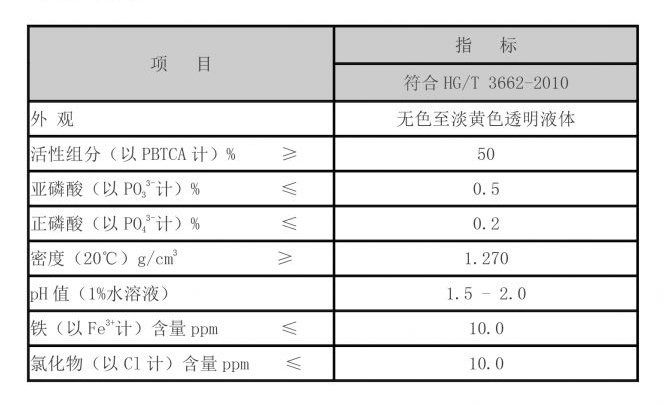

Tetra Sodium Salt of 1-Hydroxy Ethylidene-1,1-Diphosphonic Acid(HEDP·Na4)

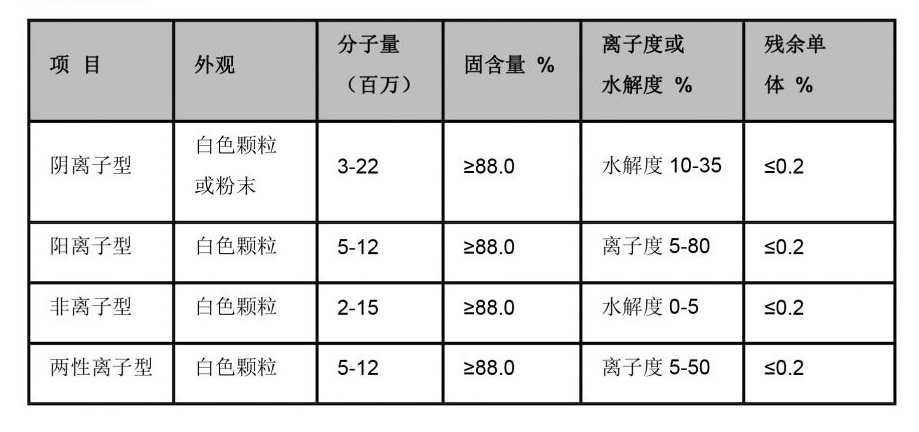

Hydrolyzed polyacrylamide, a water-soluble polymer, plays a significant role in various industrial sectors due to its remarkable properties such as high viscosity, good solubility, and the ability to increase the viscosity of water even in minimal concentrations. Its primary use revolves around water treatment processes, petroleum extraction, and paper manufacturing, making it a cornerstone in enhancing operational efficiency across these domains.

The merit of hydrolyzed polyacrylamide extends beyond these industries, contributing to environmental conservation efforts by minimizing waste and optimizing material usage. Researchers and environmental scientists advocate for its expanded use due to its low toxicity and its capacity to lower the environmental impact of heavy industrial processes. Its biodegradable nature further augments its reputation as an environmentally friendly choice. Professional skepticism, however, surrounds the long-term effects and sustainability of relying heavily on chemical additives such as hydrolyzed polyacrylamide. While current studies support its safe use, continuous research and innovation are paramount to addressing potential environmental and health concerns. Industry experts emphasize the need for robust safety protocols and continuous monitoring to ensure safe handling and disposal practices. In conclusion, hydrolyzed polyacrylamide represents both an opportunity and a responsibility within its primary industries. Its proven capabilities in increasing efficiency, reducing operational costs, and supporting sustainable practices underscore its importance as a pivotal industrial chemical. As research continues to evolve, the industry’s collective expertise culminates in optimizing its use, guaranteeing not just enhanced productivity, but also a commitment to environmental stewardship. This reflects a balance between harnessing technological innovations and adhering to the principles of sustainability and responsible usage, thus ensuring its reputable standing in industrial applications.

The merit of hydrolyzed polyacrylamide extends beyond these industries, contributing to environmental conservation efforts by minimizing waste and optimizing material usage. Researchers and environmental scientists advocate for its expanded use due to its low toxicity and its capacity to lower the environmental impact of heavy industrial processes. Its biodegradable nature further augments its reputation as an environmentally friendly choice. Professional skepticism, however, surrounds the long-term effects and sustainability of relying heavily on chemical additives such as hydrolyzed polyacrylamide. While current studies support its safe use, continuous research and innovation are paramount to addressing potential environmental and health concerns. Industry experts emphasize the need for robust safety protocols and continuous monitoring to ensure safe handling and disposal practices. In conclusion, hydrolyzed polyacrylamide represents both an opportunity and a responsibility within its primary industries. Its proven capabilities in increasing efficiency, reducing operational costs, and supporting sustainable practices underscore its importance as a pivotal industrial chemical. As research continues to evolve, the industry’s collective expertise culminates in optimizing its use, guaranteeing not just enhanced productivity, but also a commitment to environmental stewardship. This reflects a balance between harnessing technological innovations and adhering to the principles of sustainability and responsible usage, thus ensuring its reputable standing in industrial applications.

Share

Latest news

-

The Ultimate Guide to Flocculants: Transforming Water TreatmentNewsNov.01,2024

-

Improve Your Water Treatment Solutions with PolyacrylamideNewsNov.01,2024

-

Enhance Your Water TreatmentNewsNov.01,2024

-

Empower You to Achieve the Highest Standards of Water QualityNewsNov.01,2024

-

Effective Scale InhibitorsNewsNov.01,2024

-

Discover the Power of Poly Aluminum Chloride in Water TreatmentNewsNov.01,2024