2 月 . 02, 2025 00:55

Back to list

polydisperse hedp

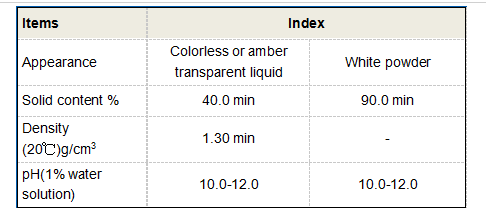

Polydisperse HEDP, or Hydroxyethylidene Diphosphonic Acid, represents a multifaceted compound widely utilized in various industrial applications due to its superior chelating properties. Its heterogeneous molecular weight distribution sets it apart from its monodisperse counterparts, offering unique advantages and challenges. Understanding the subtleties of polydisperse HEDP's chemistry and applications can provide businesses with a competitive edge, especially in sectors like water treatment, textiles, and pulp and paper production.

Despite the myriad benefits, leveraging polydisperse HEDP requires expertise to navigate potential challenges. For instance, when used in water systems that serve potable purposes, precise dosage and monitoring are essential to maintain compliance with health and safety standards. Companies investing in the use of this compound often collaborate with chemical specialists to design tailored treatment protocols that maximize HEDP's advantages while mitigating any risks of chemical overuse. Trustworthiness and reliability are built into the reputation of polydisperse HEDP due to extensive research and proven track record in various applications. Its efficacy is documented in numerous peer-reviewed studies and industrial reports, establishing it as a cornerstone in the field of industrial cleaning and processing. Furthermore, partnerships with reputable chemical suppliers ensure the consistent quality of polydisperse HEDP products, fostering trust among end-users. In conclusion, the strategic application of polydisperse HEDP can transform industry practices, offering unparalleled benefits in water treatment, textiles, and paper manufacturing. Its unique characteristics coupled with authoritative backing from industry research make it a top choice for businesses aiming to optimize operational efficiency and product quality. For those seeking to innovate within their respective industries, embracing the versatility and proven performance of polydisperse HEDP is not just an opportunity but a necessity for sustained competitive advantage.

Despite the myriad benefits, leveraging polydisperse HEDP requires expertise to navigate potential challenges. For instance, when used in water systems that serve potable purposes, precise dosage and monitoring are essential to maintain compliance with health and safety standards. Companies investing in the use of this compound often collaborate with chemical specialists to design tailored treatment protocols that maximize HEDP's advantages while mitigating any risks of chemical overuse. Trustworthiness and reliability are built into the reputation of polydisperse HEDP due to extensive research and proven track record in various applications. Its efficacy is documented in numerous peer-reviewed studies and industrial reports, establishing it as a cornerstone in the field of industrial cleaning and processing. Furthermore, partnerships with reputable chemical suppliers ensure the consistent quality of polydisperse HEDP products, fostering trust among end-users. In conclusion, the strategic application of polydisperse HEDP can transform industry practices, offering unparalleled benefits in water treatment, textiles, and paper manufacturing. Its unique characteristics coupled with authoritative backing from industry research make it a top choice for businesses aiming to optimize operational efficiency and product quality. For those seeking to innovate within their respective industries, embracing the versatility and proven performance of polydisperse HEDP is not just an opportunity but a necessity for sustained competitive advantage.

Share

Next:

Latest news

-

The Ultimate Guide to Flocculants: Transforming Water TreatmentNewsNov.01,2024

-

Improve Your Water Treatment Solutions with PolyacrylamideNewsNov.01,2024

-

Enhance Your Water TreatmentNewsNov.01,2024

-

Empower You to Achieve the Highest Standards of Water QualityNewsNov.01,2024

-

Effective Scale InhibitorsNewsNov.01,2024

-

Discover the Power of Poly Aluminum Chloride in Water TreatmentNewsNov.01,2024