1 月 . 30, 2025 00:33

Back to list

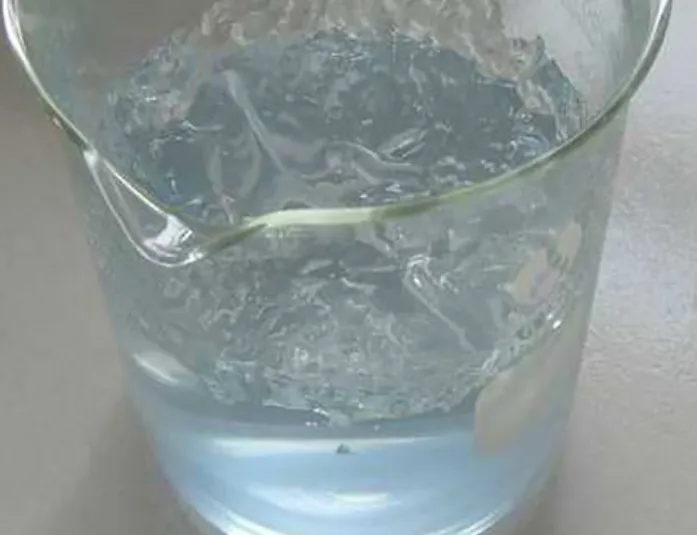

poly aluminium chloride price per kg

Navigating the fluctuating landscape of poly aluminium chloride pricing is vital for businesses reliant on this versatile chemical in water treatment and industrial applications. Having firsthand experience with this indispensable compound, I understand the intricacies involved in its procurement and pricing. Here’s a comprehensive guide on the nuances that influence the price per kg of poly aluminium chloride and what businesses should consider when making purchasing decisions.

The geographical location is another pricing determinant. Transportation costs, tariffs, and regional supplier availability can cause significant differences in price per kg of PAC across different markets. Buyers in remote regions or areas with fewer suppliers might face higher costs compared to those situated in industrial hubs with ample supply chains. Quality specifications are crucial as well. PAC is available in different grades—basicity levels vary, generally ranging between 10% to 70%, which affects its efficiency and, consequently, its cost. Buyers seeking to meet specific treatment efficiency or regulatory standards might find themselves paying a premium for higher-grade PAC. Building a trusted relationship with suppliers can provide leverage in managing price volatility. Engaging with authoritative suppliers, who offer documented proof of regulatory compliance and consistent quality assurances, not only ensures product reliability but can also offer more predictable pricing dynamics. Suppliers with robust reputations are often more transparent about price determinants and are likely to offer pricing indexed to market conditions favorably impacting long-term budgeting and planning. In conclusion, understanding the complex interplay of economic, geographic, and industrial factors is essential for mastering the poly aluminium chloride price per kg dynamics. With my expertise and in-depth knowledge, I advise businesses to maintain vigilance over global material trends, foster strategic supplier relationships, and regularly reassess their procurement strategies. Through informed and proactive management, businesses can navigate the PAC market effectively, ensuring cost-efficiency and continuity in their operations.

The geographical location is another pricing determinant. Transportation costs, tariffs, and regional supplier availability can cause significant differences in price per kg of PAC across different markets. Buyers in remote regions or areas with fewer suppliers might face higher costs compared to those situated in industrial hubs with ample supply chains. Quality specifications are crucial as well. PAC is available in different grades—basicity levels vary, generally ranging between 10% to 70%, which affects its efficiency and, consequently, its cost. Buyers seeking to meet specific treatment efficiency or regulatory standards might find themselves paying a premium for higher-grade PAC. Building a trusted relationship with suppliers can provide leverage in managing price volatility. Engaging with authoritative suppliers, who offer documented proof of regulatory compliance and consistent quality assurances, not only ensures product reliability but can also offer more predictable pricing dynamics. Suppliers with robust reputations are often more transparent about price determinants and are likely to offer pricing indexed to market conditions favorably impacting long-term budgeting and planning. In conclusion, understanding the complex interplay of economic, geographic, and industrial factors is essential for mastering the poly aluminium chloride price per kg dynamics. With my expertise and in-depth knowledge, I advise businesses to maintain vigilance over global material trends, foster strategic supplier relationships, and regularly reassess their procurement strategies. Through informed and proactive management, businesses can navigate the PAC market effectively, ensuring cost-efficiency and continuity in their operations.

Share

Latest news

-

The Ultimate Guide to Flocculants: Transforming Water TreatmentNewsNov.01,2024

-

Improve Your Water Treatment Solutions with PolyacrylamideNewsNov.01,2024

-

Enhance Your Water TreatmentNewsNov.01,2024

-

Empower You to Achieve the Highest Standards of Water QualityNewsNov.01,2024

-

Effective Scale InhibitorsNewsNov.01,2024

-

Discover the Power of Poly Aluminum Chloride in Water TreatmentNewsNov.01,2024