polyacrylamide suppliers

Understanding Polyacrylamide Suppliers A Comprehensive Guide

Polyacrylamide (PAM) is an essential polymer used widely across various industries, particularly in water treatment, agriculture, and food processing. Its unique properties, including excellent water solubility, high molecular weight, and ability to flocculate, make it a valuable product for improving efficiency and effectiveness in numerous applications. With the rising demand for polyacrylamide, the role of suppliers has become increasingly important. In this article, we will delve into who polyacrylamide suppliers are, what they do, and how to choose the right one for your needs.

Who Are Polyacrylamide Suppliers?

Polyacrylamide suppliers are companies or organizations that manufacture, distribute, and sell PAM products. These suppliers may originate from various sectors, including chemical manufacturing companies, specialty distributors, and wholesalers. They usually cater to a diverse clientele, ranging from large industrial corporations to small agricultural businesses, all requiring polyacrylamide for different applications.

Suppliers typically offer various grades of polyacrylamide, including anionic, cationic, and non-ionic forms. The choice among these grades depends on the specific use cases, such as soil conditioning, flocculation in water treatment, or as a thickener in food processing.

The Importance of Polyacrylamide in Different Industries

1. Water Treatment One of the most vital uses of polyacrylamide is in water treatment plants. It acts as a flocculant, helping to bind particles together so they can be easily removed from water. Its efficiency in this regard makes it indispensable for municipalities and industries alike.

2. Agriculture In agriculture, polyacrylamide is used to enhance soil properties. Its ability to retain water helps in reducing soil erosion and increasing crop yields, making it a sought-after product among farmers.

3. Food Processing The food industry also benefits from polyacrylamide as a thickening agent. The polymer helps achieve the desired consistency in various food products, ensuring quality and consumer satisfaction.

Choosing the Right Polyacrylamide Supplier

polyacrylamide suppliers

When selecting a polyacrylamide supplier, several factors should be taken into consideration to ensure you partner with a reputable and capable provider

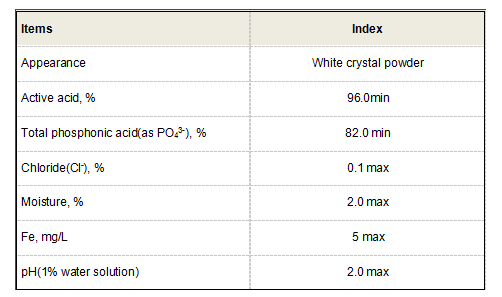

1. Product Quality Check for quality certifications and product specifications. A supplier should provide documentation that guarantees the quality and efficacy of their polyacrylamide products.

2. Variety of Offerings A good supplier should offer a range of polyacrylamide grades tailored to different applications. This variety enables customers to find the most suitable product for their specific needs.

3. Experience and Reputation Consider the supplier’s track record in the industry. Established suppliers with a positive reputation are likely to provide better service and higher-quality products.

4. Technical Support It’s beneficial if the supplier offers technical assistance or consultancy. They should be able to provide guidance on product application and best practices, ensuring that customers achieve optimal results.

5. Pricing and Supply Chain Reliability Choose a supplier who offers competitive pricing without compromising quality. Additionally, a reliable supply chain is crucial to ensure timely delivery of products as production schedules can be tightly interwoven with material availability.

6. Sustainability Practices With growing concerns about environmental impact, consider suppliers who implement sustainable practices in their manufacturing processes. This not only benefits the planet but can also enhance your company’s corporate responsibility profile.

Conclusion

In conclusion, polyacrylamide suppliers play a pivotal role in a variety of industries by providing essential products that enhance processes and outcomes. Understanding the significance of polyacrylamide and selecting the right supplier can greatly impact the effectiveness of your application—be it in water treatment, agriculture, or food processing. By considering factors such as product quality, variety, and supplier reliability, businesses can ensure they meet their operational needs efficiently. Partnering with the right polyacrylamide supplier can lead to improved quality, operational efficiency, and overall business success.

-

The Ultimate Guide to Flocculants: Transforming Water TreatmentNewsNov.01,2024

-

Improve Your Water Treatment Solutions with PolyacrylamideNewsNov.01,2024

-

Enhance Your Water TreatmentNewsNov.01,2024

-

Empower You to Achieve the Highest Standards of Water QualityNewsNov.01,2024

-

Effective Scale InhibitorsNewsNov.01,2024

-

Discover the Power of Poly Aluminum Chloride in Water TreatmentNewsNov.01,2024