1 月 . 15, 2025 09:15

Back to list

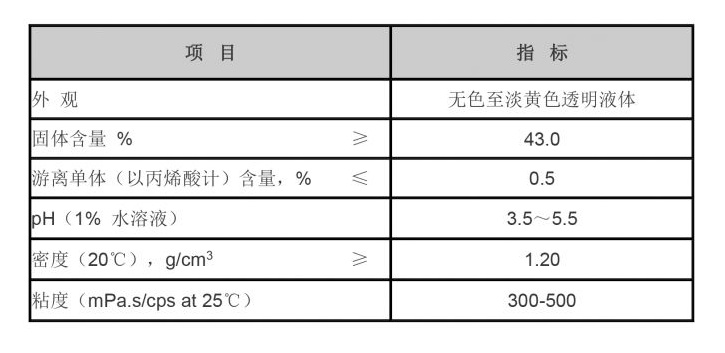

corrosion scale inhibitor

Corrosion scale inhibitors play a pivotal role in preventing and mitigating the detrimental effects of corrosion and scaling in various industrial systems. These inhibitors are essential for ensuring the longevity, efficiency, and safety of equipment used in industries such as oil and gas, water treatment, and chemical processing. Drawing from years of field experience and scientific research, it is clear that selecting the right corrosion scale inhibitor involves understanding both the chemical properties of the inhibitor and the specific conditions of the industrial system.

Incorporating corrosion scale inhibitors into a preventive maintenance program offers a strategic advantage. It allows companies to proactively manage risks associated with corrosion and scaling, reducing unscheduled downtime and maintenance costs. The investment in high-quality inhibitors is often offset by the savings from avoiding extensive repair work and the unexpected replacement of equipment. Finally, the pursuit of environmentally friendly corrosion scale inhibitors is gaining prominence. Innovations are leading towards biodegradable and non-toxic inhibitors that meet environmental regulations while maintaining performance standards. As the industry evolves, it is imperative to stay informed about the latest advancements in inhibitor technology and regulatory requirements. In conclusion, the selection and application of corrosion scale inhibitors demand a blend of experience, specialized knowledge, authoritative guidance, and a commitment to trustworthy practices. By focusing on these core principles, industries can ensure sustainable, efficient, and safe operations, safeguarding costly assets against the pervasive threat of corrosion and scale build-up.

Incorporating corrosion scale inhibitors into a preventive maintenance program offers a strategic advantage. It allows companies to proactively manage risks associated with corrosion and scaling, reducing unscheduled downtime and maintenance costs. The investment in high-quality inhibitors is often offset by the savings from avoiding extensive repair work and the unexpected replacement of equipment. Finally, the pursuit of environmentally friendly corrosion scale inhibitors is gaining prominence. Innovations are leading towards biodegradable and non-toxic inhibitors that meet environmental regulations while maintaining performance standards. As the industry evolves, it is imperative to stay informed about the latest advancements in inhibitor technology and regulatory requirements. In conclusion, the selection and application of corrosion scale inhibitors demand a blend of experience, specialized knowledge, authoritative guidance, and a commitment to trustworthy practices. By focusing on these core principles, industries can ensure sustainable, efficient, and safe operations, safeguarding costly assets against the pervasive threat of corrosion and scale build-up.

Share

Next:

Latest news

-

The Ultimate Guide to Flocculants: Transforming Water TreatmentNewsNov.01,2024

-

Improve Your Water Treatment Solutions with PolyacrylamideNewsNov.01,2024

-

Enhance Your Water TreatmentNewsNov.01,2024

-

Empower You to Achieve the Highest Standards of Water QualityNewsNov.01,2024

-

Effective Scale InhibitorsNewsNov.01,2024

-

Discover the Power of Poly Aluminum Chloride in Water TreatmentNewsNov.01,2024