3 月 . 06, 2025 17:31

Back to list

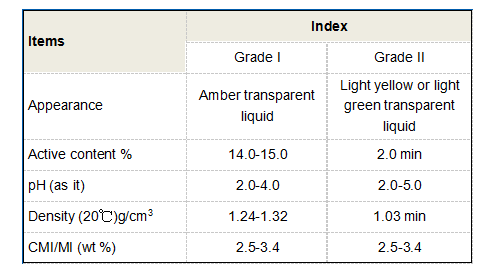

PAC Poly Aluminum Chloride

Coagulation and flocculation are pivotal processes used in water treatment systems to ensure water safety and clarity. Understanding these processes is vital for professionals in the water purification industry, where expertise and trust are paramount.

In practice, plant operators are trained meticulously in the science of coagulation and flocculation, understanding the delicate balance between under-dosing and overdosing coagulants. This expertise is critical; overdosing can lead to poor water quality and increased costs, while under-dosing allows harmful pathogens to persist, posing risks to public health. Therefore, continuous monitoring and adjustments are necessary to maintain the integrity and safety of the treated water. The effectiveness of the coagulation and flocculation process directly impacts the plant's credibility and trustworthiness in the community it serves. Frequent water quality testing is conducted to ensure compliance with environmental standards and to meet the community's expectations for clean and safe water. The results of these tests are often shared publicly, building community trust and demonstrating the plant's commitment to transparency and quality assurance. In conclusion, coagulation and flocculation represent a critical intersection of science and engineering, requiring a high level of experience to execute effectively. With proper implementation and monitoring, these processes not only improve water quality but also reinforce the authority of water treatment facilities within their communities. By investing in state-of-the-art technology and dedicated personnel, plants can enhance not only their operational success but also the well-being and confidence of the populations they serve.

In practice, plant operators are trained meticulously in the science of coagulation and flocculation, understanding the delicate balance between under-dosing and overdosing coagulants. This expertise is critical; overdosing can lead to poor water quality and increased costs, while under-dosing allows harmful pathogens to persist, posing risks to public health. Therefore, continuous monitoring and adjustments are necessary to maintain the integrity and safety of the treated water. The effectiveness of the coagulation and flocculation process directly impacts the plant's credibility and trustworthiness in the community it serves. Frequent water quality testing is conducted to ensure compliance with environmental standards and to meet the community's expectations for clean and safe water. The results of these tests are often shared publicly, building community trust and demonstrating the plant's commitment to transparency and quality assurance. In conclusion, coagulation and flocculation represent a critical intersection of science and engineering, requiring a high level of experience to execute effectively. With proper implementation and monitoring, these processes not only improve water quality but also reinforce the authority of water treatment facilities within their communities. By investing in state-of-the-art technology and dedicated personnel, plants can enhance not only their operational success but also the well-being and confidence of the populations they serve.

Share

Latest news

-

The Ultimate Guide to Flocculants: Transforming Water TreatmentNewsNov.01,2024

-

Improve Your Water Treatment Solutions with PolyacrylamideNewsNov.01,2024

-

Enhance Your Water TreatmentNewsNov.01,2024

-

Empower You to Achieve the Highest Standards of Water QualityNewsNov.01,2024

-

Effective Scale InhibitorsNewsNov.01,2024

-

Discover the Power of Poly Aluminum Chloride in Water TreatmentNewsNov.01,2024